One of the most important and essential materials for advancing construction projects is cement and concrete blocks. In the past, the raw materials for making blocks were manually mixed, block molds were made by hand, materials were poured into the molds, and finally, after the blocks were ready, they were manually removed from the mold by hand pressure. This process, in addition to being time-consuming, never resulted in the desired outcome, and the blocks produced manually lacked good quality. The biggest flaw of manual block molding was that the blocks would crack, which was due to insufficient hand pressure for shaping the concrete.

Today, with technological advances, block-making machines have taken on a new form. Join us in this article from Beton Sarmad to explore the different types of block-making machine molds.

What types of molds are there for block-making machines?

The mold for each block-making machine is determined based on the type of machine. This means that if your machine is manual, the block mold will be one model, and if it's automatic, the mold will be different. Therefore, it’s better to first review the types of block-making machines before discussing the different molds:

- Manual Block Making Machine

- Semi-Automatic Block Making Machine

- Automatic Block Making Machine

As mentioned, each of these machines has its own specific molds, differing in productivity and the number of blocks produced per day. Let’s now review each of these machines and their required molds in more detail.

Manual Block Making Machine Mold

Don’t be mistaken. This machine has no similarity to the traditional block molding system. It is the simplest concrete block-making machine, also called an egg-layer machine. The reason it’s called an egg-layer is because the block production method is similar to how egg-layers function.

The working method of this machine is that the mortar is manually poured into the molds, and then, by pressing a lever, the materials inside the molds are compressed. Once the block takes the shape of the mold, the machine moves forward and creates the next row of blocks, just like an egg-layer that moves forward after laying its eggs.

Semi-Automatic Block Making Machine Mold

The semi-automatic machine is named as such because it has an intermediate quality between manual and automatic machines. In this machine, part of the molding process, such as vibration, is done automatically, and its pressure lever is hydraulic. As expected, working with this machine is much easier than the traditional molding machine, and the size of the blocks produced is also much more precise. Similar to the manual machine, the semi-automatic block machine also operates like an egg-layer, moving from one mold to the next.

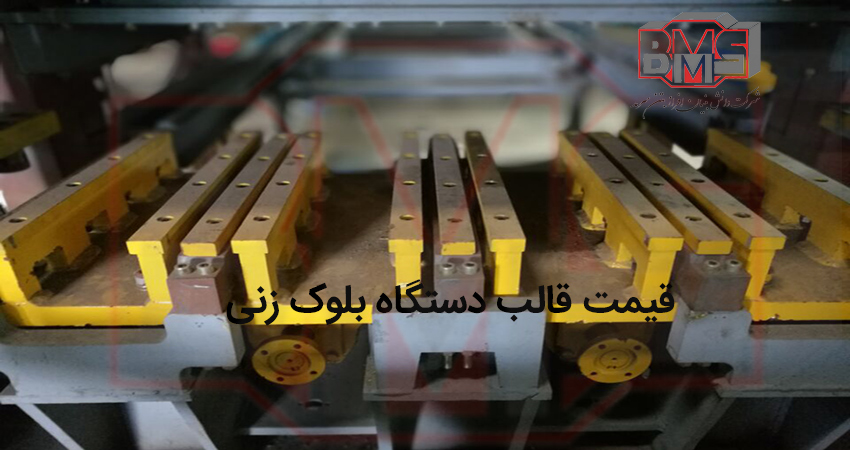

Automatic Block Making Machine Mold

Working with this machine is easier than both the other machines, and the blocks produced by it have the highest quality. The block-making process with this machine is fully automated, without any human intervention, and the machine itself does not move. The machine is equipped with a conveyor belt that, after producing the concrete blocks, moves and transports the completed blocks out of the machine.

Although the molds for automatic block-making machines are more expensive than the other two models, consider that investing in such a machine is a good investment.

Number of molds in block-making machines

The number of molds in each of the machines mentioned differs from the others. Manual block-making machines typically have four molds. In semi-automatic machines, this number increases to five, and in automatic machines, it reaches six, eight, or eleven molds. Note that the number of molds in each machine can vary depending on the manufacturer’s brand. Changing the block-making machine mold differs between manual and automatic machines and is performed differently for each type of machine.

Block Making Machine Mold Price

The price of a block-making machine mold depends on several important factors, which are as follows:

- Material of the mold: Molds are typically made from steel (for durability and long-term use) or aluminum (for lighter weight and lower cost). Steel molds are generally more expensive than aluminum molds.

- Size and dimensions of the mold: Molds are designed for producing blocks of various sizes. Larger molds or those with more complex designs may cost more.

- Type of block produced: Molds used for producing specialized blocks, such as insulated blocks, ceiling blocks, or decorative blocks, generally have different costs.

- Quality and manufacturing precision: The quality of the mold and its precision in producing standard-sized blocks can have a significant impact on the price.

- Production volume: Molds designed for mass production and high output can be more expensive, especially if their design and construction are complex.

- Additional features: Molds with special features such as automatic opening and closing systems, corrosion-resistant coatings, or other unique capabilities may be more expensive.

- Economic conditions and market: Fluctuations in raw material prices, production costs, and the overall economic situation can affect mold prices.

The price of simple and small molds may start from about 5 to 20 million Toman, while medium molds with special features may range from 20 to 50 million Toman. Larger industrial molds designed for mass production or specialized blocks can cost between 50 million to 100 million Toman or even more. For more accurate pricing, contact our consultants at Beton Sarmad.

Specifications of Manual Block Making Molds

Manual block-making molds, as essential tools in the construction industry, are used for producing various types of cement blocks. These molds, with their simple and practical features, allow users to produce high-quality cement blocks. One of the advantages of these molds is that they do not require complex and expensive equipment. Manual molds are typically made from materials like steel or iron, which give them high resistance to impact and repeated pressure. This makes them suitable for use in various working environments, including small construction workshops and rural areas where access to advanced equipment is limited.

These molds, due to their simple design, are ideal for smaller projects or workshops with limited budgets. Additionally, the relatively light weight of manual molds makes them perfect for transport over long distances or for use in areas with inadequate infrastructure. Due to their portability and ease of use, manual molds are typically used for low to medium-scale block production. Generally, those looking to start a block-making business with low investment can benefit from these molds.

Specifications of Single Manual Block Making Molds

Single manual block-making molds are designed to produce only one block at a time. This type of mold allows the user to have more precise control over the production process and produce high-quality and uniform blocks. Key features of these molds include accuracy in dimensions and block compaction. The user can manually pour and compress the cement material into the mold, which ensures the production of strong, high-quality blocks.

These molds are typically made from durable and high-quality materials like steel, which makes them resistant to wear and pressure. Moreover, due to their simple design and reliance on manual labor, single molds are suitable for those who need to produce blocks on a small scale. These molds are often used in renovation projects, small wall constructions, or rural areas that require low-volume blocks.

Buying Cement Block Molds

Buying cement block molds is one of the most crucial steps for producing high-quality blocks in construction projects. When purchasing cement block molds, several key factors should be considered. The first and most important factor is the quality of the mold materials. Molds made from stainless steel and wear-resistant materials are the best option for use in various working environments. Steel, due to its strength and durability, ensures that the mold lasts longer and requires fewer repairs or replacements.

Besides the material quality, mold design is also important. Molds with precise and engineered designs can produce blocks with consistent dimensions and standards, which is critical in construction. Blocks produced from high-quality molds typically have greater strength and are more suitable for large-scale construction projects.

Another factor to consider when buying a mold is its compatibility with the project’s requirements. Manual molds are suitable for small projects and block-making workshops, while automatic or semi-automatic molds are better for larger projects and mass production. These molds can produce more blocks in less time and reduce production costs.

Finally, the price of the mold should be carefully evaluated. Molds made from high-quality materials may have a higher price but are more cost-effective in the long run due to their durability and efficiency. On the other hand, molds made from cheaper materials may lower initial investment costs but may lead to more frequent repairs or replacements.

Beton Sarmad: Best Block Making Machines and Molds

Beton Sarmad is one of the leading suppliers of block-making machines and molds. Our company offers a variety of block-making molds and machines to meet different construction needs. We provide manual, semi-automatic, and automatic block-making machines, along with molds designed for producing high-quality blocks. All our products are manufactured using the highest quality materials to ensure durability and precision in production.

At Beton Sarmad, we understand the importance of investing in high-quality equipment for construction projects. Our molds and machines are designed to offer the best performance, whether you are producing blocks for small projects or large-scale construction works.

If you need more information on block-making molds or are ready to purchase, feel free to contact our consultants for guidance and assistance.